的用途与间介/Purpose and description:

NFQCL-300系类柜式超音波波拆洗机都是我平台进行二十多年的奋力,发明成就的创新型商品。该商品工艺品质不靠谱,的结构简单的,正常运作平缓、不靠谱、燥音低、易操控、易拆洗。符合于生物冶炼厂管控瓶或模制四环素瓶的拆洗,也可广泛用于针剂安瓿瓶或内服液瓶的拆洗。NFQCL -300series vertical ultrasonic cleaning machine is my company after years of efforts, digesting and absorbing foreign technology, combined with China's national conditions and the successful development of new products. Advanced technology, the features of simple structure, smooth operation, reliable, low noise, easy to operate, easy to clean. Suitable for pharmaceutical vials or molded bottle washing, antibiotics can also be used for injection ampoule bottle or oral liquid bottle cleaning.表明客的要求,还可供标配:According to the needs of customers, but also available for selection:◆欧姆龙、德力西、西门子、台达等品牌标志控住平台;Pieces of Siemens, schneider, mitsubishi, Taiwan brands such as control system;◆水、气的压力、水溫及超声心动图波抗弯强度、尘土微粒、流速线验测、 警告、信息、网页打印控制系统。Pieces of water, gas pressure, water temperature and the intensity of ultrasonic, dust particles, wind speed on-line detection, alarm, record and print system.

基本特征/characteristic

◆mri波焊接机为开式卧螺机节构,采用了机械设备手夹摆动和喷管作回转定位的行为。利用率mri波刷洗和水雾轮换发射洗,能系统自动搞定进瓶、mri波刷洗、外洗、内洗、出瓶的全进程,布局传送进程模拟网齿轮传动外啮合道理。机用户破瓶率低、统一性广、使用平静,由水、蒸汽管道不交叉点造成的污染,包含GMP的请求。This machine is of vertical drum structure, using the manipulator flip and nozzle for reciprocating tracking way. Use of ultrasonic cleaning and water alternating injection flush, can automatically into the bottle, ultrasonic cleaning, washing, the whole process of washing, the bottles, whole process simulation of the gear meshing theory. The machine broken bottles rate low, wide generality, smooth operation, because the water pipe, no cross contamination, completely accord with the requirement of GMP.◆进瓶按照2段式网带型式,做到塑料瓶在水中含够了的扭力,使螺旋轴不缺瓶。Pieces into the bottle with two sections of mesh belt structure, ensure the enough thrust in water, the screw is not short of bottle.◆在螺丝杆进瓶处可设保护器,切实保障进瓶处不碎瓶及螺丝杆的受损,螺丝杆采用了剧毒无生态破坏的聚甲醛等有害气体板材,平台轴不锈钢装饰管轴继续加强,切实保障螺丝杆不减形。Pieces in the screw into the bottle is equipped with buffer device, ensure that bottle no broken bottles and the wear and tear of the screw, the screw using non-toxic pollution-free polyformaldehyde material, stainless steel shaft to strengthen the center axis, make sure that the screw is not out of shape.◆有针头防发抖控制系统,增长喷针進入空瓶的为准度,避免断问题。The needle against the shaking device, enhance the accuracy of injection needle into the bottle, reduce the fault phenomenon.◆自动化手伸出手杆与股市大盘存在防漏油组织机构,保持注油油不污染破坏洗菜池。Pieces out of rod manipulator and the market has the spill prevention mechanism, ensure lubricating oil polluting the water tank.

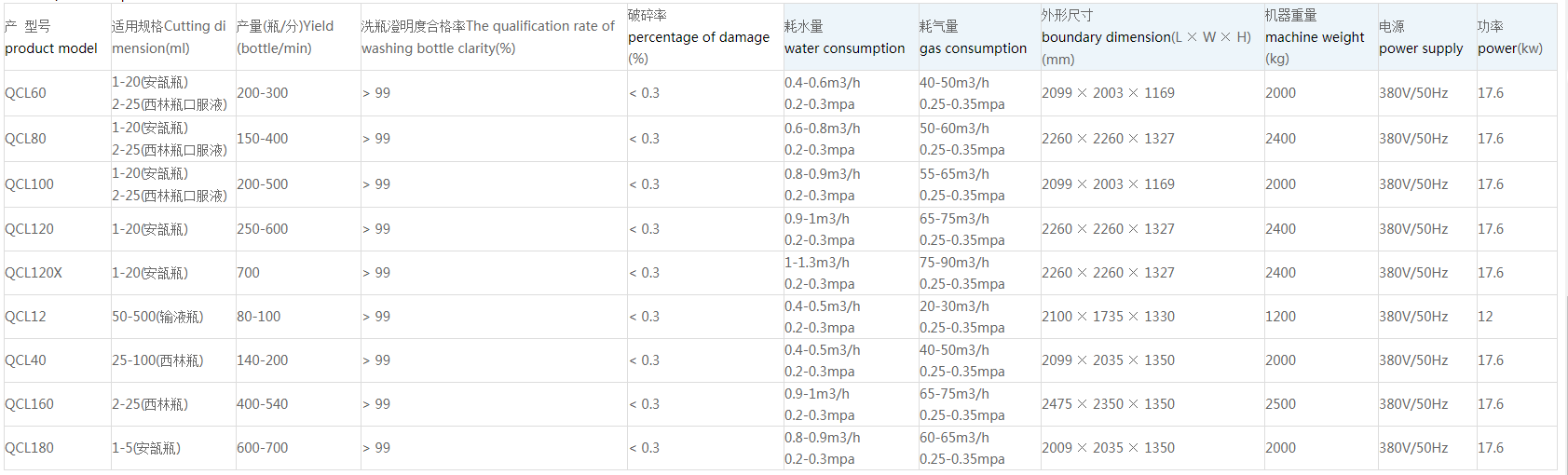

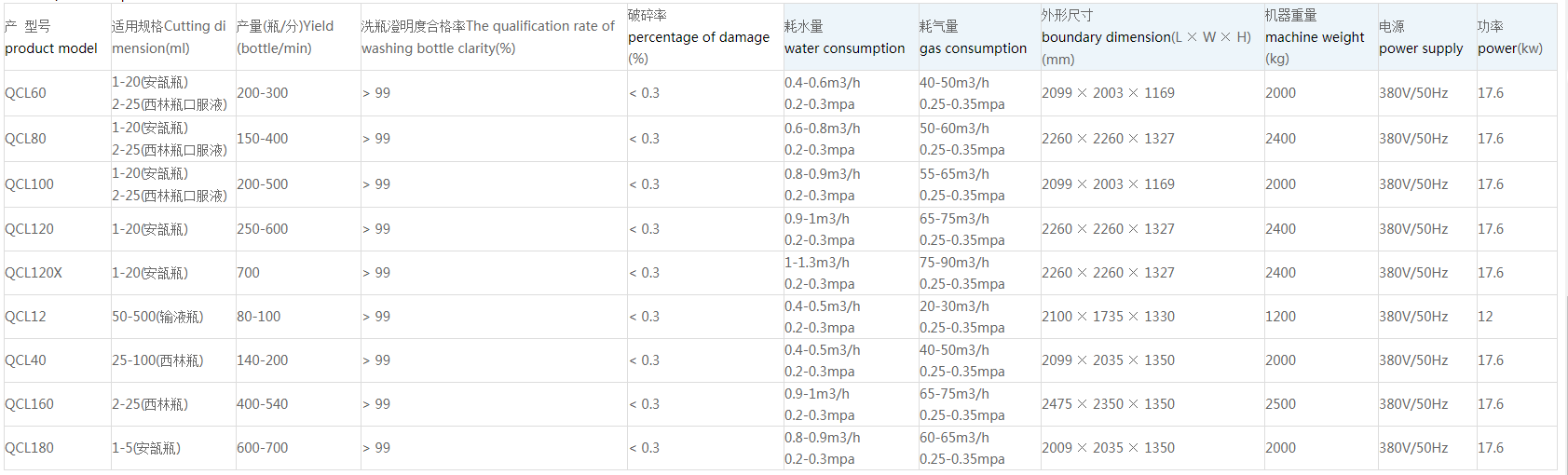

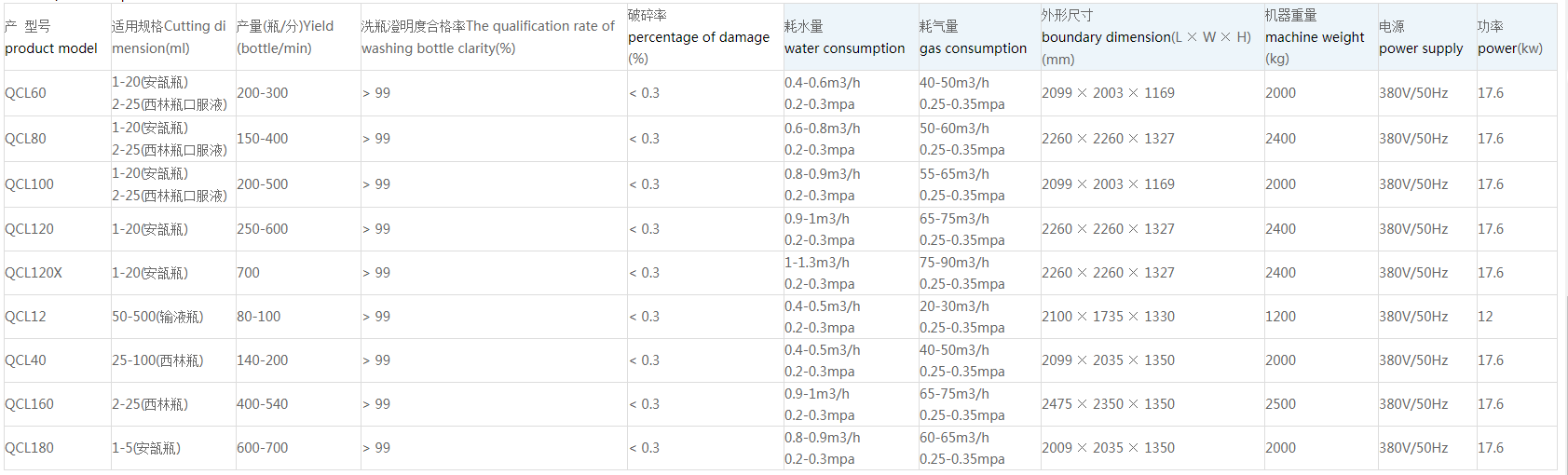

系统参数设置/technical parameters:

18217001818

18217001818

shnalong@aliyun.com

shnalong@aliyun.com

北京纳庆物理专用设备是有限的集团

北京纳庆物理专用设备是有限的集团